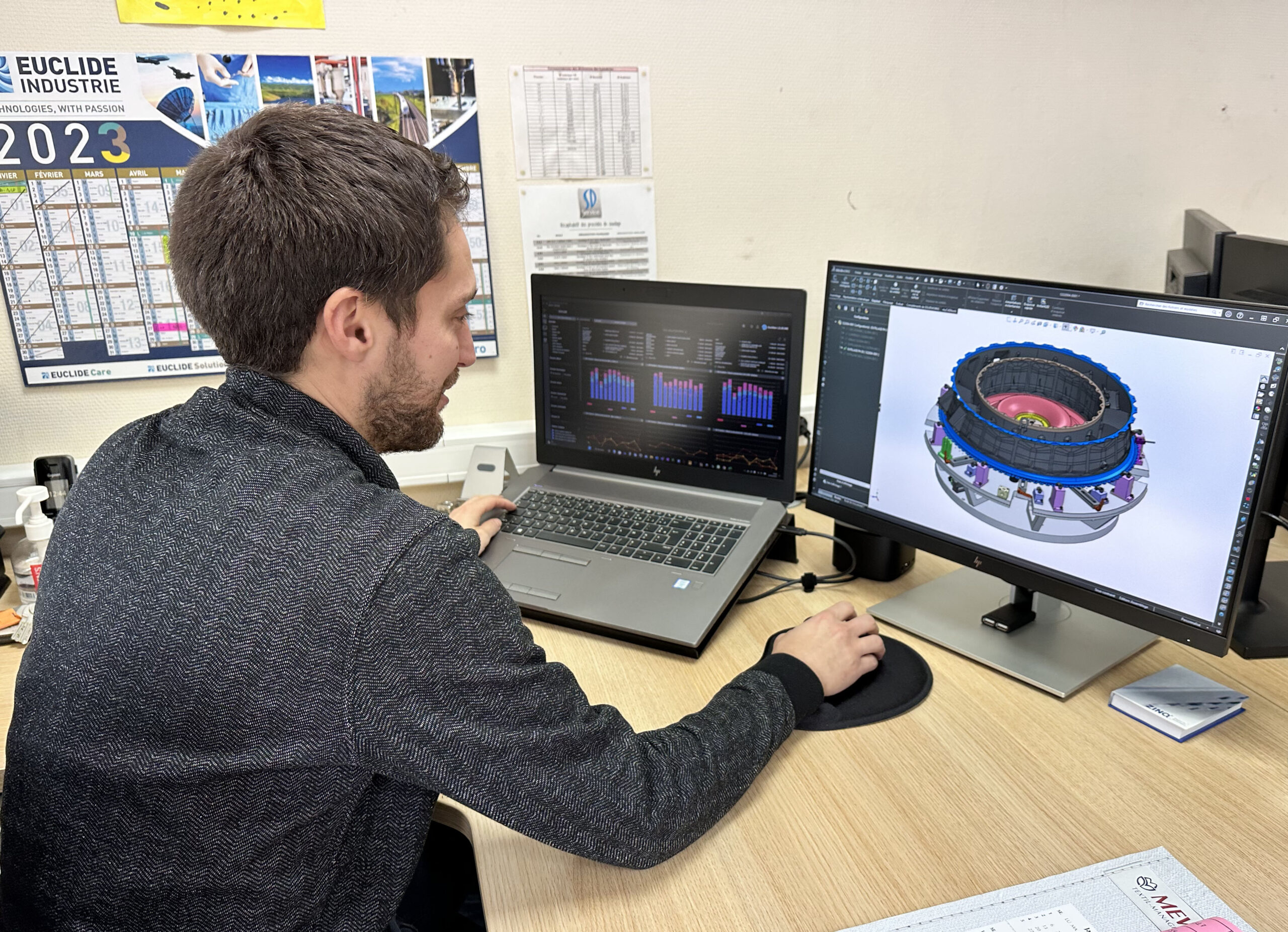

Mallevialle plant, machining specialist

It is grouping the last generation machining tools for 3 and 5-axis milling, 4-axis turning, EDM and grinding (profile and deep reach), making possible to realize complex & high precision mechanical assemblies.

Our mechanical know-how is also well known in the field of production tools such as elastomer and composite molds, pultrusion dies, cutting/stamping tools.